Table of Contents

SAP FI-MM Integration Configuration steps

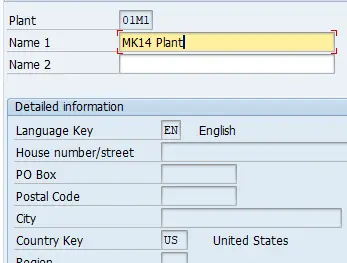

Define Plant

- A ‘Plant’ is an operating area or a branch or a location within a company. Each ‘Plant’ is assigned to a single ‘company code’. A ‘company code’ can have several ‘Plants’

- IMG Path: Enterprise Structure -Definition – Logistics general – Define, copy, delete, check plant

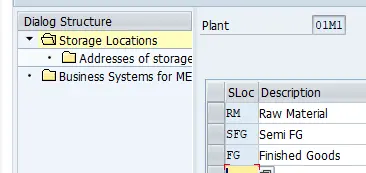

Define Storage Location

A storage location is the place where stock is physically kept within a plant. There may be one or more storage locations within a plant.

- IMG Path: Enterprise Structure -Definition – Materials Management – Maintain Storage Location

- Tcode: OX09

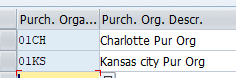

Maintain Purchase Organization

The purchasing organization is the highest level of aggregation (after the organizational unit “client”) for purchasing statistics.

IMG Path: Enterprise Structure – Definition – Materials Management – Maintain Purchasing Organization

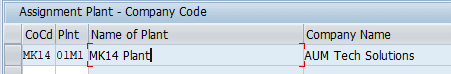

Assign Plant to Company Code

A Plant needs to be assigned to one of the Company Codes, the relation is always one to one i.e. One Plant can be assigned to only one company code

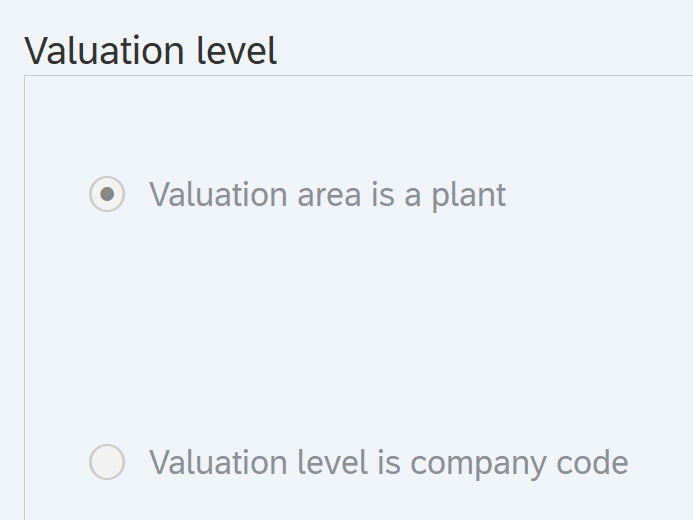

However, before plant is assign to company code, we have to define Valuation Level. Materials are valued at valuation level.

Define Valuation Level: OX14

Assign Plant to Company Code

Path: Enterprise Structure -Assignment – Logistics general – Assign Plant to Company Code

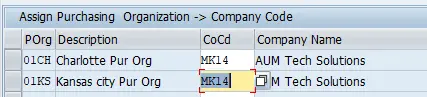

Assign Purchase Organization to Company code

IMG Path: Enterprise Structure – Assignment – Material Management – Assign purchasing organization to company code

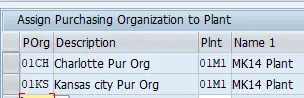

Assign Purchase Org to Plant

IMG Path: Enterprise Structure -Assignment – Logistics general – Assign purchasing organization to Plant

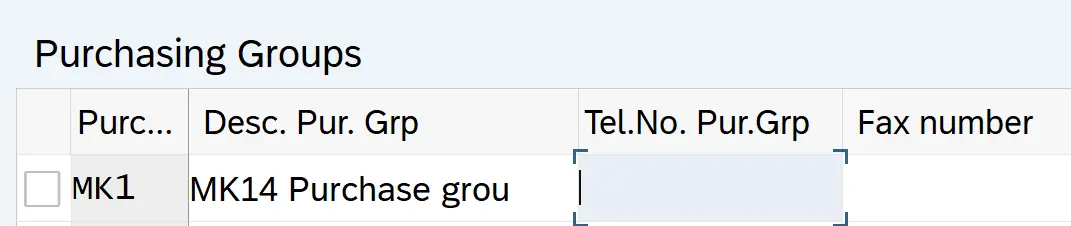

Purchasing Groups

Path: SPRO – Material Management – Purchasing – Create Purchasing Group

A Purchasing group refers to a people or a group of people who are dealing with specific material or a group of material

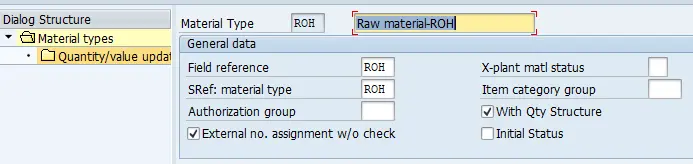

Define Attributes for Material Type

Material Type is a Logical grouping of materials that are similar in characteristics. Any material master record created in SAP ERP must be assigned to a material type.

IMG Path: Logistics – General – Material Master – Basic Settings- Material Types- Define Attributes of Material Types

Transaction Code: OMS2

| Material Type | Description |

| ROH | Raw Material |

| FERT | FG Type |

| HALB | Semi FG type |

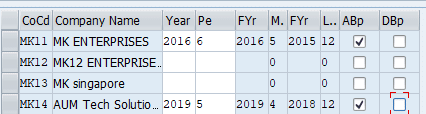

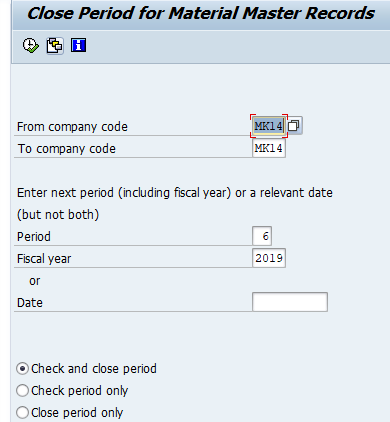

Maintain Posting Period

This activity is done for making a Company Code relevant for Materials Management and to define the starting posting period

IMG Path: Logistics – General -Material Master – Basic Settings- Maintain Company Codes for Materials Management

Transaction Code: OMSY

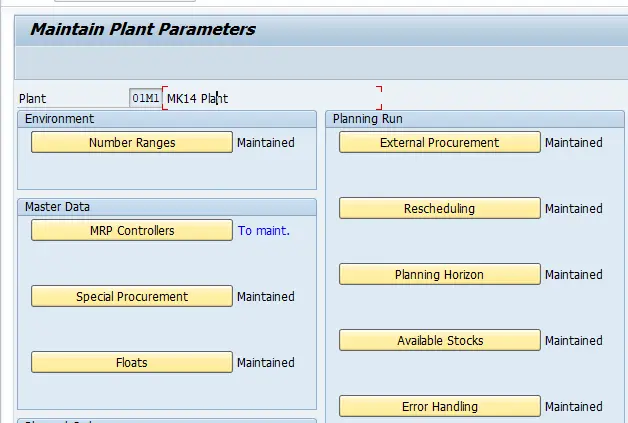

Creation of Plant Parameters

Transaction code: OMI8

Copy from plant 1000 to our plant 01M1

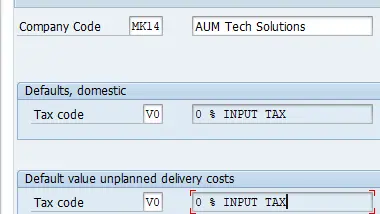

Default values of Tax code for Invoice Verification

Path: SPRO -Materials Management – Logistic Invoice verification – Incoming Invoice – Maintain Default Tax code

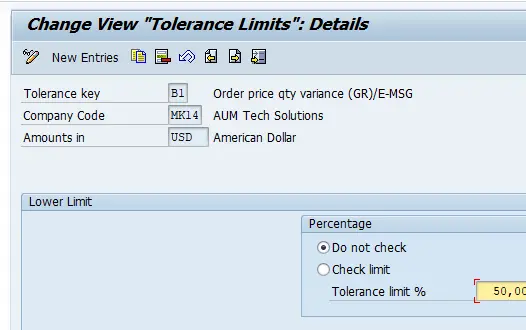

GR Tolerance Group

In this step, we set the tolerance limits for goods receipts. When processing a goods receipt, the system checks each item to determine whether the goods receipt varies from the purchase order or the material master data. The different types of variances are defined by tolerance keys. For each tolerance key, tolerance limits can be set per

company code.

Path: SPRO -Material Management – Inventory Management – Good Receipt – Set Tolerance

Copy Tolerance B1, B2 and VP from company code 1000 to MK14

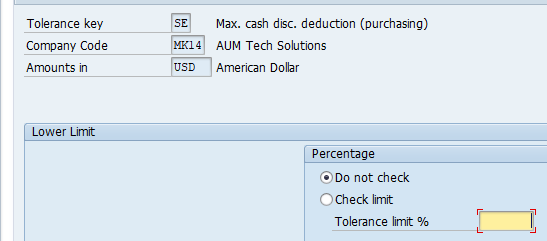

Set Tolerance limit for Price Variance

When processing a purchase order, the system checks whether the effective price of a PO item shows variances compared with the valuation price stored in the material master record. In addition, it checks whether the specified cash discount value is admissible.

Variances are allowed within the tolerance limits. If a variance exceeds a tolerance limit, the system issues a warning or error message. In SAP, the types of variance are represented by the tolerance keys.

Path: SPRO –Material Management – Purchasing – PO – Set Tolerance limit for price variance

Copy Tolerance limit PE, SE from company code 1000 to MK14

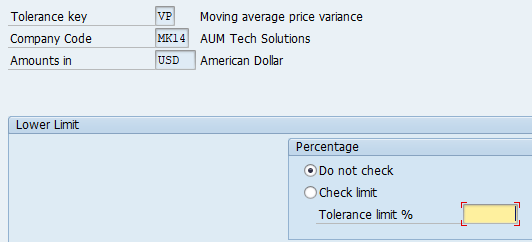

Set Tolerance limit for price difference between Invoice and Purchase order

IMG Path: Material Management – Logistic Invoice verification – Invoice block – Set Tolerance

Copy price variance PP and VP from company code 1000 to MK14

Define Automatic Status Change

Transaction Code: OMRV

Invoice verified in the background. If found correct, status automatically set to completed

![]()

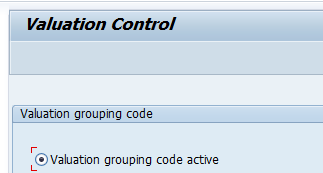

Define Valuation Control

It defines if the valuation areas will be grouped by activating the valuation grouping code. In the standard SAP R/3 System, the valuation grouping code is set to active as default setting.

Transaction code: OMWM

IMG Path: Materials Management -> Valuation and Account Assignment -> Account Determination -> Account Determination without Wizard-> Define Valuation Control

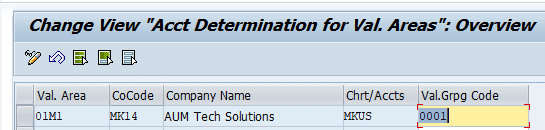

Group Together Valuation area plant

Path: Material Management – Valuation and Account Assignment – Account Determination – Account Determination without wizard – Group together valuation area

Transaction Code: OMWD

In the standard SAP system, valuation is predefined at plant level. All plants are grouped together via valuation grouping code 0001. Assign SAP define valuation grouping 0001 to Plant 01M1

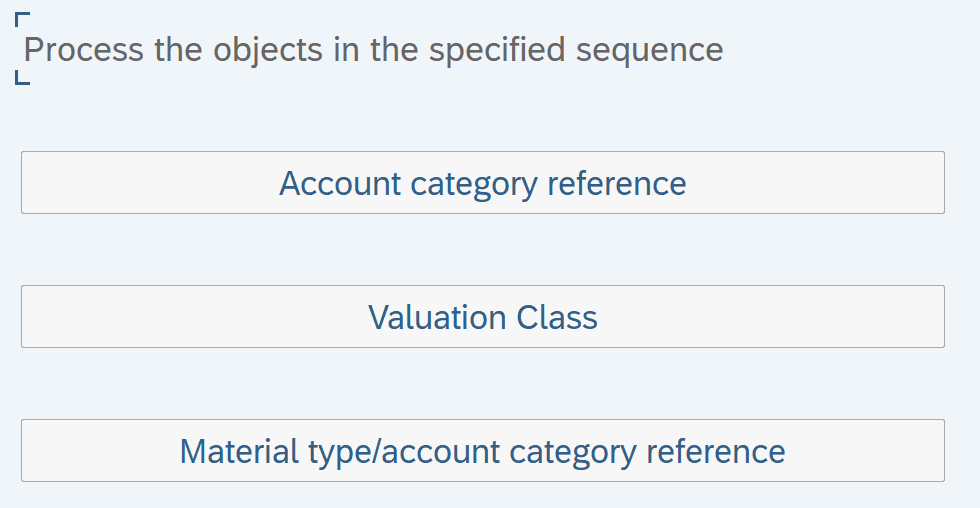

Define Valuation Classes

IMG Path: Materials Management -> Valuation and Account Assignment -> Account Determination -> Account Determination without Wizard->Define Valuation Classes.

Transaction Code: OMSK

| Valuation Class / Acct Cat Reference | Description |

| Valuation Class | A grouping of Material |

| Account Category Reference | Grouping of Valuation Classes |

| Material Type | Logical Grouping of material with similar characteristic |

| Material Type and Account Category Reference assignment | Material Types are assigned to Account category Reference. This links Material types to valuation class and to GL accounts to which posting should happen |

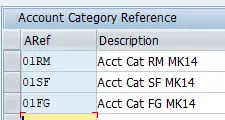

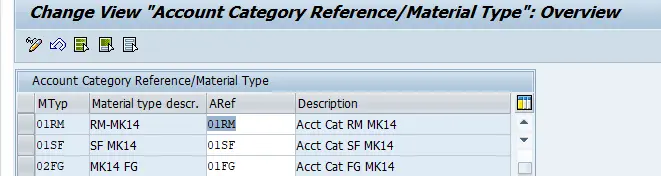

Account Category Reference

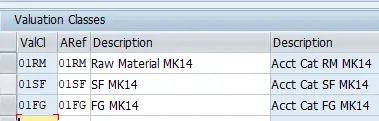

Valuation Class

Transaction Code: OMSK

Material Type and Account Category Reference

Transaction Code: OMSK

Change Movement Type

In this step we define or change Movement Types

When we enter a goods movement, we must always enter the movement type. The movement type has important control functions in Inventory Management. It is essential for

- Updating the quantity fields

- Updating the stock and consumption accounts

- Printing goods receipt/issue slips

IMG Path: Materials Management -Inventory Management and Physical Inventory – Movement Types – Copy, Change Movement Types

Transaction Code: OMJJ

We will use the default SAP movement types.

| Movement Type | Allowed Transaction |

| 101 | Goods Receipt |

| 261 | GI for order |

Creation of Various GL accounts for FI-MM Integration

Transaction Code: FS00

| Description | GL Acct | Type | Line Itm. | Sort Key | FSG | Post Auto |

| RM Local | 200108 | BS/Cr. Liabilities | X | 012 | G006 | X |

| GRIR Clearing Acct | 100510 | BS/Cr. Liabilities | X | 012 | G045 | X |

| PO and Invoice Price Diff Acct | 400203 | PL/Mnf. Exp | X | 001 | G003 | X |

| RM Consumption Local | 400000 | PL | X | 001 | G003 | X |

| RM Consumption Import | 400001 | PL | X | 001 | G003 | X |

| Tax Payable | 100511 | BS | X | 001 | G001 | – |

For detailed, step-by-step instructions on SAP Cost Center Accounting, Product Costing, Profit Center Accounting, Internal Orders, FI-MM Integration follow along with my video tutorial below

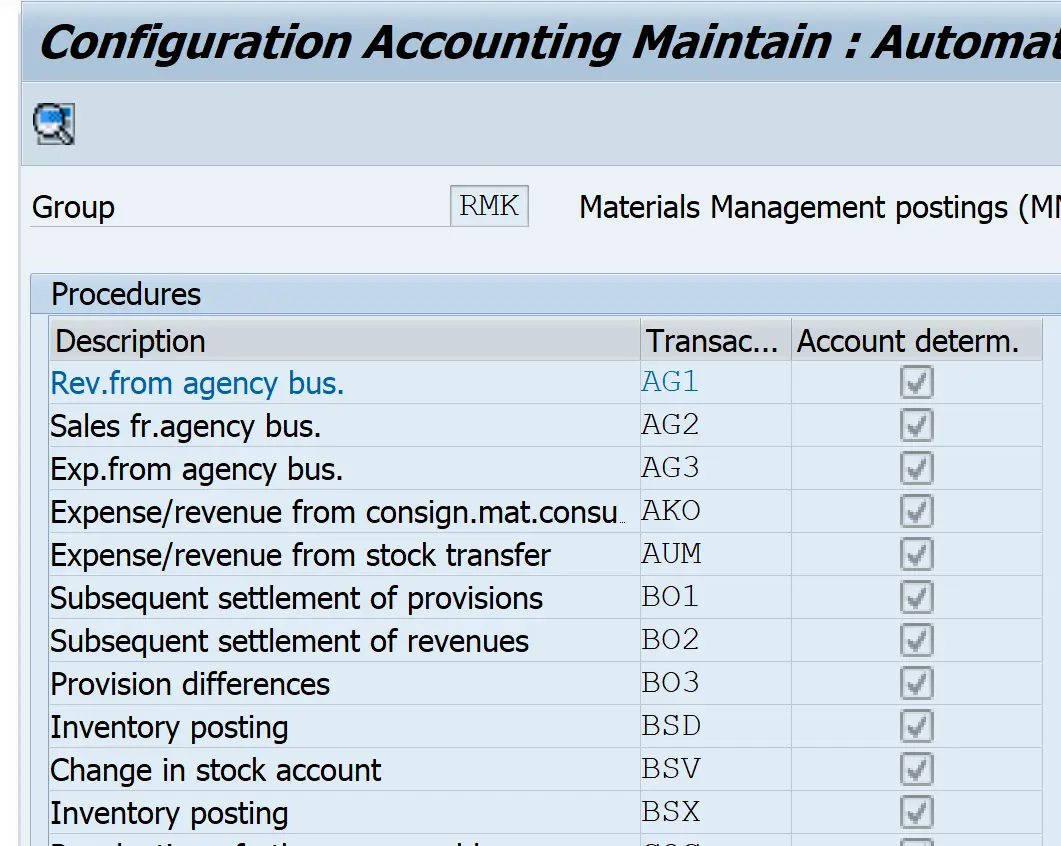

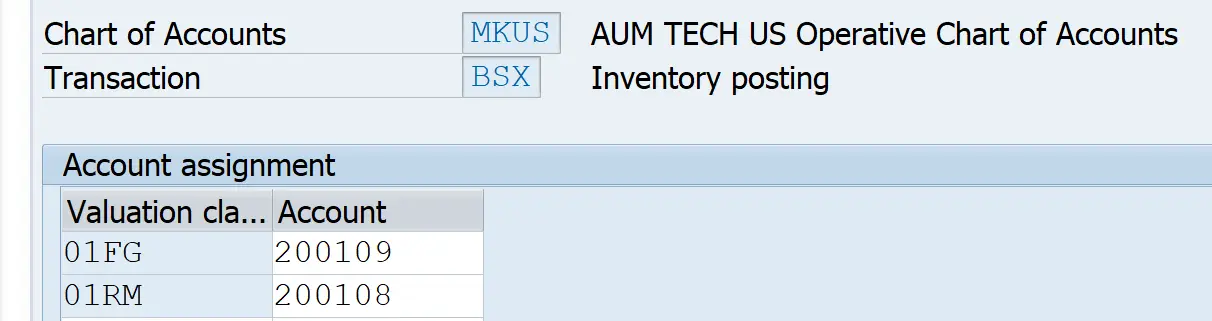

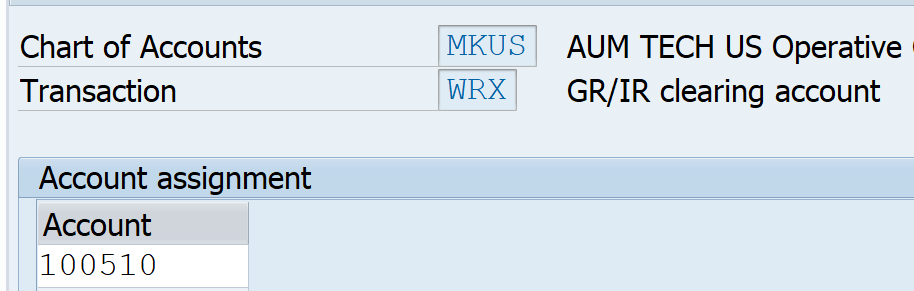

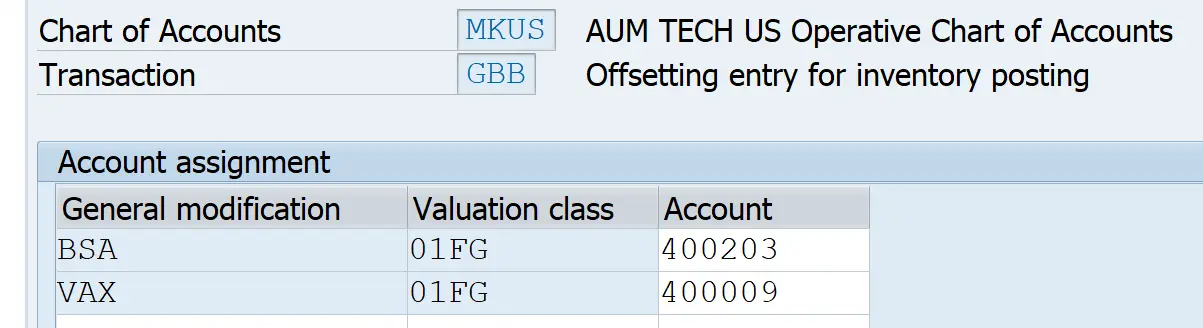

Configure Automatic Account Posting: FI-MM Integration

Transaction Code: OBYC

| Transaction Key | Description | Valuation Class | Gen MODIF | GL Acct |

| BSX | Inventory Posting | 01RM | 200108 | |

| WRX | GRIR Clearing Account | 01RM | 100510 | |

| PRD | Price Diff Account | 01RM | 400203 | |

| GBB | Offsetting Entry for Inventory Posting | 01RM | VBR | 400001 |

| BSX | Inventory Posting | 01FG | 200109 |

BSX

WRX

GBB

Extend Vendor Master to Purchase Organization

Transaction Code: XK01

However, before the above step Partner function must be created for Vendors

| Steps | Path | Data |

| Define Partner Schemas | SPRO / Materials Management / Purchasing / Partner Determination / Partner Settings in Purchasing Documents / Define Partner Schemas | No Change. SAP standard |

| Define Settings for Vendor Master Records: | SPRO / Logistics – General / Business Partner / Vendors / Control / Define Account Groups and Field Selection (Vendor) | Partner schemas: IDE1 |

| Assign Partner schemas to Vendor account groups | SPRO/ Mm / Purchasing / Partner determination / Partner Settings in Vendor Master Record- Assign Partner Schemas to Account Groups | Partner schemas: IDE1 |

| Define Permissible Partner Roles per Account Group | SPRO-Materials Management-Purchasing-Partner Determination-Define Permissible Partner Roles per Account Group |

Create Material

Transaction Code: MM01

| Material | MK14RM01 |

| Industry | MECHANICAL Eng. |

| Material Type | RM MK14 |

| Views | Basic, Accounting 1, 2, Costing 1,2 |

| Plant | 01M1 |

| Storage Location | RM |

| Unit of Measure | Kg |

| Material Group | 00104 |

| Purchase Group | MK1 |

| MRP-1 | |

| MRP Type | ND |

| MRP – 2 | |

| Proc Type | F (External) |

| RM Storage Loc | RM |

| Planned Del Time | 1 |

| Accounting -1 | |

| Valuation Class | 01RM |

| Price Control | V: Moving Average |

| Moving Price | 200 |

| Costing -1 | |

| With Qty Structure | X |

| Material Origin | X |

Material MK14RM01 created

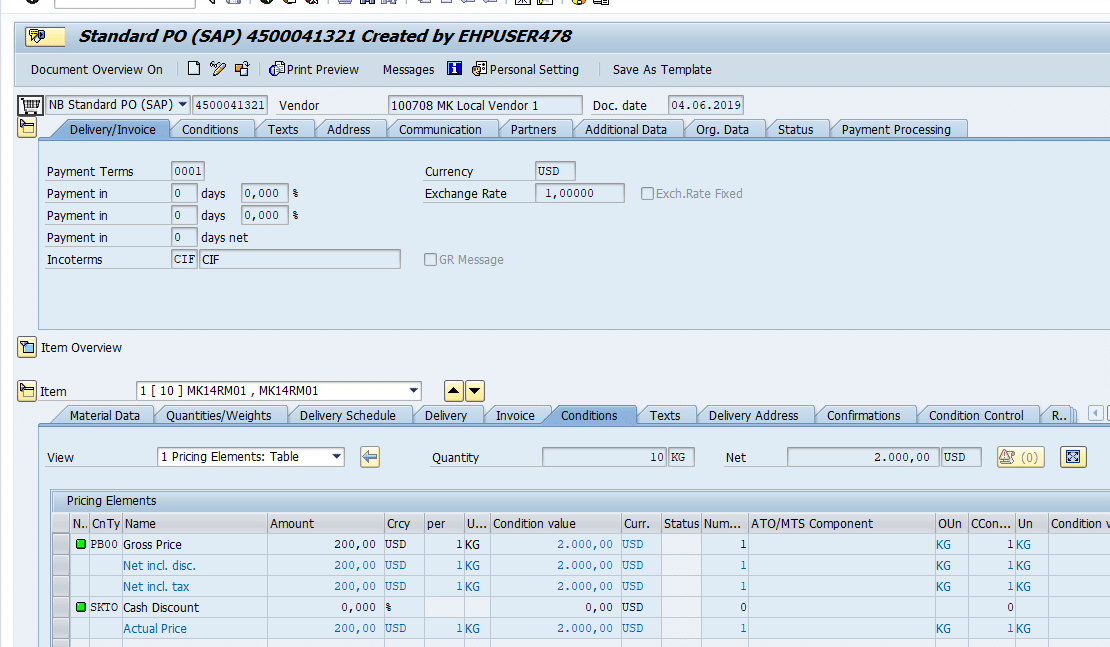

Create Purchase Order

Transaction Code: ME21N

Standard PO (SAP) created under the number 4500041321

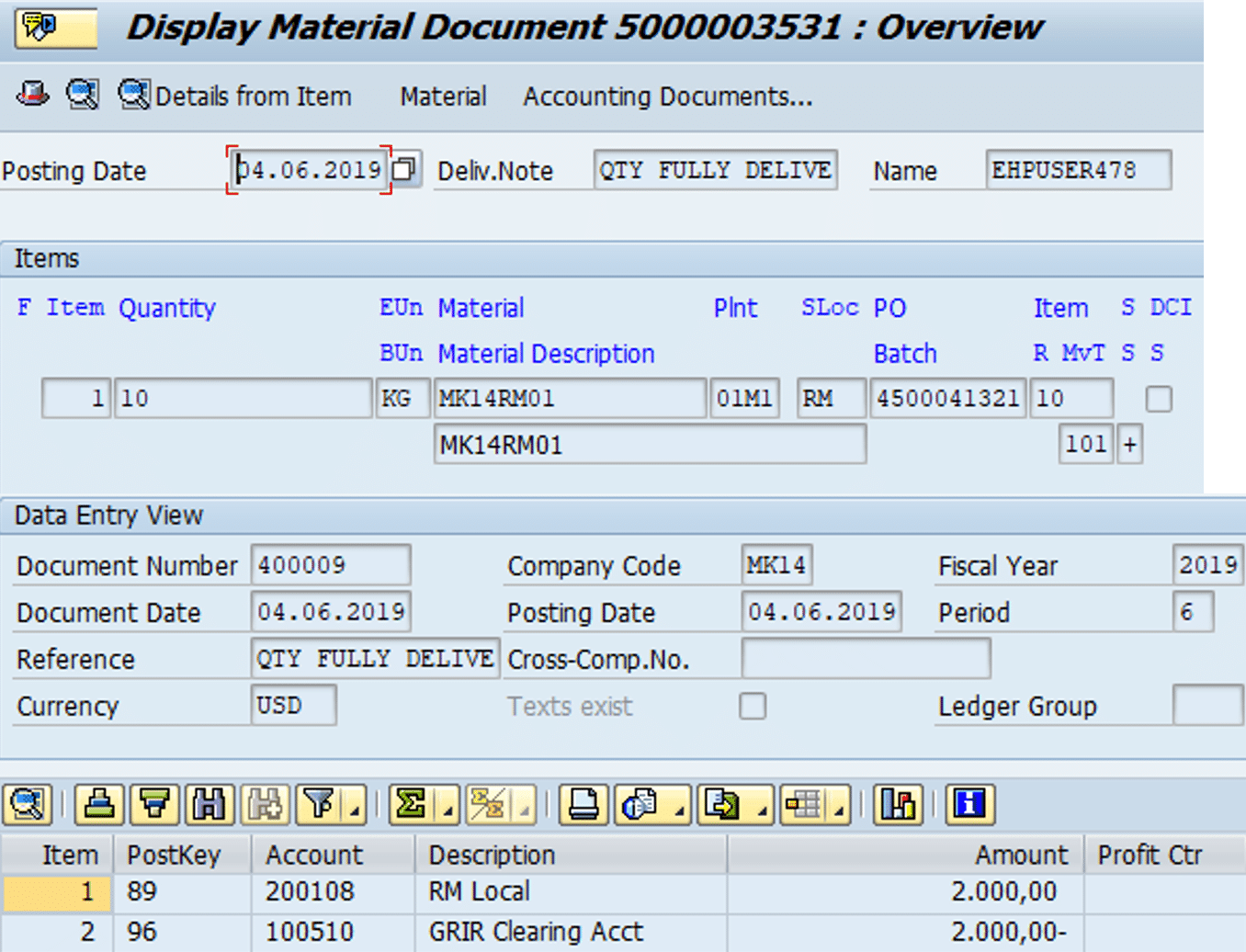

Create Good Receipt

Transaction Code: MIGO

Close previous MM Period and Open current MM period: MMPV

Material document 5000003531 posted. Display Material Document: MB03

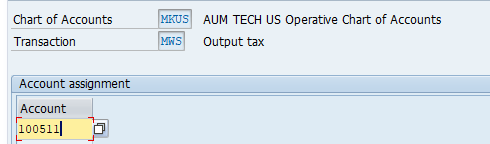

Automatic Posting for Tax account

Create Tax Payable GL account

Transaction code: FS00

Transaction code: OB40

Transaction Key: MWS

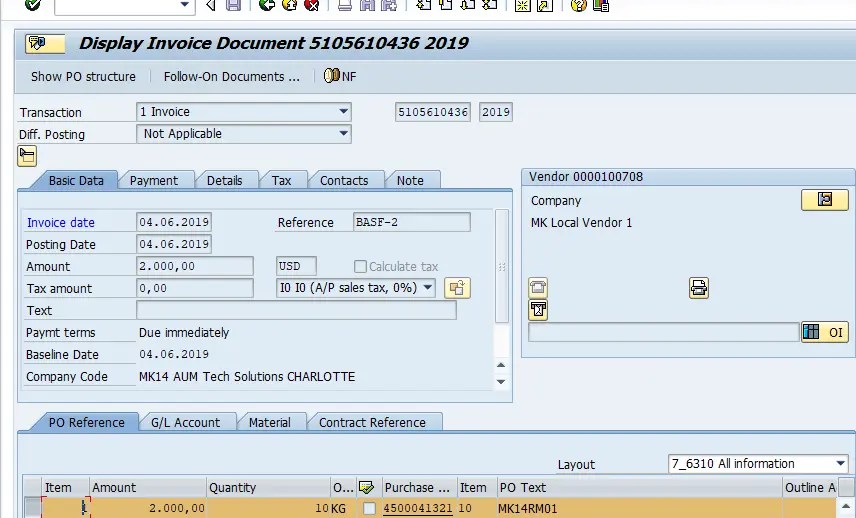

Create Purchase Order Invoice

Transaction code: MIRO

Pingback: SAP Technical | AUMTECH Solutions-SAP Training

Pingback: SAP Tutorials | AUMTECH Solutions-SAP Training

Pingback: SAP FICO Interview Questions & Answers | AUMTECH Solutions-SAP Training

Pingback: Vendor Consignment Process In SAP | AUMTECH Solutions-SAP Training